8 Year Exporter Automatic Plastic Bag Feeder - desk-top feeder – Baiyi

8 Year Exporter Automatic Plastic Bag Feeder - desk-top feeder – Baiyi Detail:

Introduction

Series of desk-top feeder adopts friction principle to realize product feeding. It is desktop design and suit for small space. Highly integrated these three function modulars: friction product feeding, transport and auto collection. At present, we have three such desk-top feeders: 1,desk-top friction feeder(Model:BY-TF01-400);2. desk-top baffle type feeder(Model:BY-TF04-300);3. intelligent desk-top friction feeder(Model:BY-TF02-400).

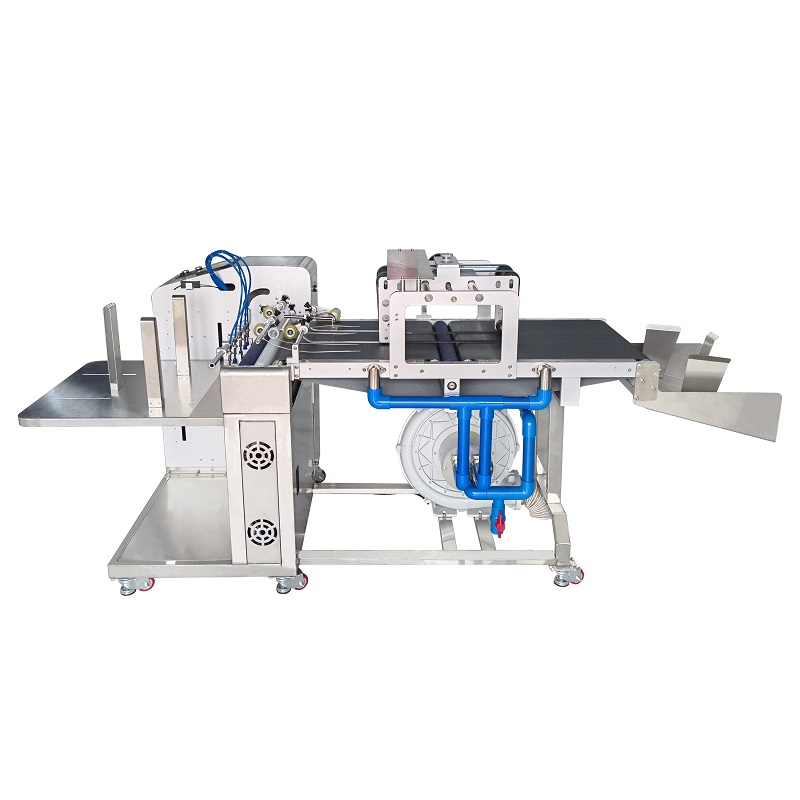

1. “desktop friction feeder” adopts stainless steel for the whole machine body. Friction feeding belt as feeding power, it is equipped with high friction belt matching kinds of friction pressing belt, which makes it an extensive usage, suit for kinds of plastic bags, especially light, thin, soft material packing bag. The thinnest product can be 0.02mm. it is with cantilever structure, loading and wearable belt changing is very convenient.

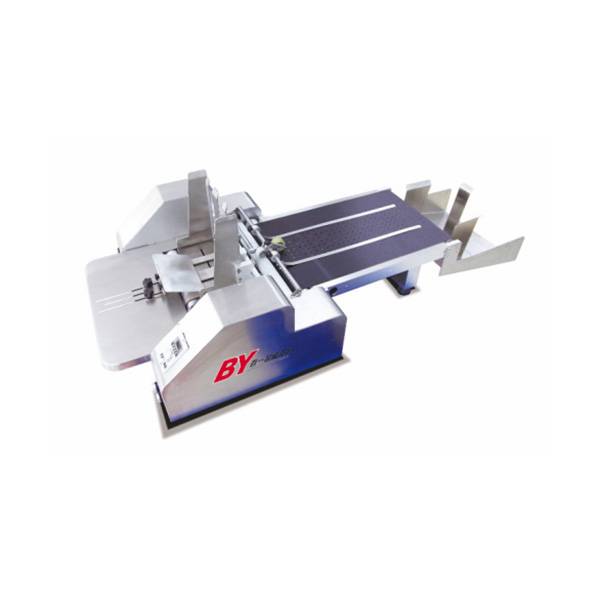

2. “desktop baffle type feeder”adopts” baffle separation” principle, single friction feeder as feeding power, no friction pressing belt, which make it suit for “thick, hard and heavy” paper box, cards and plate product. Meanwhile, the wearable to belt is the minimum, friction is stable and easy to control, so the feeding effect is stable and speed fast. Users can consider to install friction pressing belt, which is suit for kinds of plastic bags. The two belts are perfectly compatible. It is with widest application range, size small, weight light, speed fast and the strongest material versatility. The max thickness for product can be 10mm.

3. ”Intelligent desk-top friction feeder” is different to “desk-top friction feeder” based on the adopting 3pcs or even more width difference friction belts as feeding power and equipped with friction pressing belt modular which is easy to change and adjust. Because of this, greatly improved the feeder’s available ability, operation and usage experience. The product width can be from 25mm to 400mm. furthermore, the friction pressing belt modular is with independent micrometer adjustment, product change is very convenient, thickness adjustment is very precise.

Drawing for Reference

1. desk-top friction feeder’s drawing

2. desk-top baffle-type feeder drawing

3. Intelligent desk-top friction feeder

Technical Parameter

1. desk-top friction feeder parameter

A. Dimension: L * W * H = 1700 * 760 * 210mm(conveyor belt width 400mm)

B. weight: 50KG

C. Voltage: 220VAC 50/60HZ

D. Power: about 500W

E. efficiency: 0-300pcs/min (take 100mm product for reference)

F. belt working speed: 0-60m/min(adjustable)

G. available product size: L * W * H = (60-400) * (80-380) * (0.05-3)mm

H. speed control method: Frequency conversion or brushless DC speed adjustment

I. motor: frequency conversion or brushless DC motor.

J. available product: kinds of paper, plastic bags, cards, labels etc. Especially suit for light, thin and soft plastic bags.

K. machine body: stainless steel

L. installation method: independent installation , desk-top.

M. optional function: fan with vacuum suction, auto collection, auto-rejection.

2. desk-top baffle-type feeder parameter

A. dimension: L * W * H = 1300 * 635 * 150mm(conveyor belt width 300mm)

B. weight: 35KG

C. voltage: 220VAC 50/60HZ

D. Power: about 500W

E. efficiency: 0-300pcs/min (take 100mmproduct size for example)

F. belt working speed: 0-60m/min (continuously adjustable)

G. available product size: L * W * H = (60-300) * (60-280) * (0.1-3)mm

H. Speed control method: frequency conversion or brushless DC speed adjustment.

I. motor: frequency conversion or brushless DC motor

J. available product: kinds of paper, plastic bags, cards, label etc. especially suit for thick, hard and heavy paper box, cards, plates etc.

K. machine body: stainless steel

L. installation method: independent installation, desktop.

N. optional function: fans of vacuum suction, auto-collection, auto-rejection.

3. intelligent desk-top feeder

A. dimension: L * W * H = 1700 * 760 * 210mm(Conveyor belt width 400mm)

B. weight: 50KG

C. voltage: 220VAC 50/60HZ

D. Power: about 500W

E. efficiency: 0-300pcs/min (take 100mmproduct size for example)

F> belt working speed: 0-60m/min(continuous adjustment)

G. available product size: L * W * H = (60-400) * (30-380) * (0.05-3)mm

H. Speed adjustment method: frequency conversion or brushless DC speed adjustment.

I. Motor: Frequency conversion or brushless DC motor

J. Available product: kinds of paper, plastic bags, cards, labels, packing box etc.

K. machine body: stainless steel.

L. installation method: independent installation, desk-top.

M. Optional function: fan with vacuum suction, auto-collection, auto-rejection.

Product detail pictures:

Related Product Guide:

Sticking towards the theory of "Super Good quality, Satisfactory service" ,We are striving to become a superb business enterprise partner of you for 8 Year Exporter Automatic Plastic Bag Feeder - desk-top feeder – Baiyi , The product will supply to all over the world, such as: Grenada, Albania, Uganda, Selling our products causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.