Factory Cheap Business Card Printing Machine - Normal feeder – Baiyi

Factory Cheap Business Card Printing Machine - Normal feeder – Baiyi Detail:

Feature

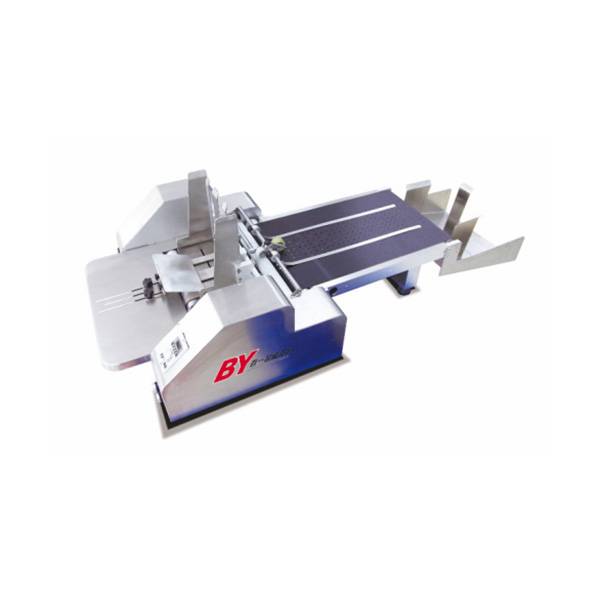

Series of normal feeder adopts friction principle to realize feeding & transport, which is our oldest feeding product and it is also the origin of “intelligent feeding technology” because of its simple structure, fast speed, commercial and easy operation, it is very popular in food industry, medicine industry, electrical and packaging industry. It satisfy normal feeding market.

According to feeding feature, there are three types of feeder: 1. Friction feeder (model BY-F01-350); 2, Reversal wheel feeder ( Model: BY-F02-300); 3. Flash board feeder (model: BY-F03-330). It includes product feeding, transport & collection. All models adopt stainless steel lightweight design, which satisfy fast installation requirement and it can be put into production after turning on. There are a lot of optional functions, which is suit for kinds of requirement. High in availability. It is suit for normal paper, label, paper box, plastic bags etc. packaging product. People can select to be equipped with CIJ printer, TIJ printer, labeling module, laser printer for text information.

Furthermore, these three types of feeder all adopt friction down-feeding mode, which satisfy production adding without machine stop. It can be equipped with vacuum suction function, which make the product running on the belt, no slip, no offset, the product surface is flat, which is good for printing and other technologies. It is equipped with auto collection function, overlap design, which make the product stack one by one and collect in orders. Meanwhile, the collection device can be customized making according to requirement.

Reference Drawing

1. friction feeder reference

2. Reversal wheel feeder reference drawing

3. flash board feeder reference drawing

Technical parameter

Friction feeder technical parameter

1. dimension: L * W * H = 1850 * 350(belt width) * 760mm

2. weight: 55KG

3. voltage: 220VAC, 50/60HZ

4. Power: about 500W

5. efficiency: 0-300pcs/min(take the product size 100mm for reference)

6. belt running speed: 0-60m/min(continuous adjustment)

7. available product size: L * W * H = 60-300 * 80-350 * 0.1-3mm

8. speed adjustment method: Variable frequency or brushless DC motor

9. motor: Variable frequency or brushless DC motor

10. available product: kinds of paper, plastic bag, cards, labels etc.

11. machine body material: stainless steel

12. installation method: independent installation, floor stand

13. optional configuration: double detection, vacuum suction function, auto collection as conveyor

Reversal wheel feeder technical parameter

1. dimension: L * W * H = 1860 * 300(belt width) * 760mm

2. weight: 60KG

3. voltage: 220VAC

4. Power: about 500W

5. efficiency: 0-300pcs/min(take the product size as 100mm for reference)

6. belt running speed: 0-60m/min(continuous adjustment)

7. available product size: L * W * H = 60-300 * 60-300 * 0.1-3mm

8. Speed control method: Variable frequency or brushless DC motor

9. motor: Variable frequency or brushless DC motor

10. available product: kinds of easy-scratch paper, plastic bags, cards, labels etc.

11. machine body: stainless steel

12. installation method: independent installation, floor stand.

13. optional functions: avacuum suction function, auto collection with conveyor.

Flash board feeder technical parameter

1. dimension: L * W * H = 1850 * 330(belt width) * 760mm

2. weight: 55KG

3. Voltage: 220VAC, 50/60HZ

4. power: about 500W

5. efficiency: 0-300pcs/min(take the product size as 100mm for reference)

6. belt running speed: 0-60m/min(continuous adjustment)

7. available product size: L * W * H = 60-300 * 80-330 * 0.5-5mm

8. speed control method: Variable frequency or brushless DC motor

9. motor: Variable frequency or brushless DC motor

10. available product: kinds of paper box, normal plastic bags, cards, normal labels etc.

11. machine body: stainless steel

12. installation method: independent installation, floor stand.

13. optional function: vacuum suction, auto collection with conveyor.

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our improvement strategy for Factory Cheap Business Card Printing Machine - Normal feeder – Baiyi , The product will supply to all over the world, such as: Iran, luzern, Slovenia, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The items to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.