Factory directly Diy Uv Printer Factories - Feeding & printing platform in special industry & special availability – Baiyi

Factory directly Diy Uv Printer Factories - Feeding & printing platform in special industry & special availability – Baiyi Detail:

Feature

Model:corresponding to each drawing

Feeding & printing platform for special industry & special availability, was developed according to the special requirement in industry application, which is based on our advance feeding technology & mature design experience. It is fast in speed, stable in performance and high target. It is direct to industry application pain point, there is one good user operation experience. This platform adopts the best structure design, the key part all elect first-class brand to make sure its stability. patent technology, accurate process technology as well as serious quality control method make this series platform have a strong brand advantage.

According to the application industry, it can be separated into 5 equipment: 1. veterinary drugs, pesticides, seed, Chinese medicine, normal food packaging industry, people can adopt intelligent feeding & TTO thermal printing machine (Model: BY-TF01-TTO); 2. veterinary drugs, pesticides, seed, Chinese medicine, normal food packaging industry, people can adopt intelligent feeding & UV printing platform (Model: BY-TF01/02-400UV); 3. hotpot material packaging, people can adopt normal feeding & UV printing machine (Model: BY-SF04-400UV);

4. people can adopt advance UDI code (ordinary code) inspection & rejection platform in medical device industry(Model:BY-HTF01-400/BY-HTF02-400) 5. people can adopt advance UDI code (UV code) inspection & rejection platform in medical device industry.(Model:BY-HTF01-400UV/BY-HTF02-400UV); In addition, we are also making positive technological breakthroughs in industries such as “household paper”, “baked food”, and “degradable tableware”. Welcome to your inquiry!

Feeding & coding platform’s design feature in special industry:

1. Feeding method adopt “static friction” principle, which is convenient for separating head to suit for kinds of packing material. Exclusive use makes the feeding effect much better.

2. Friction force is precisely adjusted with a micrometer. No need special training then cam operate well.

3. Non- cantilever wall panel design is adopted on both sides, sufficient rigidity to ensure feeding stability, low in double sheet feeding. Double detection system is reliable which is an optional function. High speed & stable.

4. Feeding system discards traditional fix friction method, the standard feeder is changed to be with 3 friction belts structure, integrated with “separating head” module, which is with our patent static friction or multi feeding belt layout. mostly suit for different size, kinds of material, uneven thickness and zipper packaging bags with seal, not easy to left scratch on the product surface.

5. Streamlined design, the appearance is more textured. Sufficient material ensures the stability even at a high speed.

6. Adopts double DC motor for speed control, enough torque output to ensure conveyor’s stability, low speed or high speed, both can be guaranteed constant speed. Then the following technology can go well. Smooth, low in noise, low in power consume as well.

7. Adopt ultra-resistant friction belt, which is not easy to drop slag or powder, sufficient oxidation resistance & acid & high temperature resistance. Long service time and not pollute the packaged product. Truly meet food-grade requirements.

8. Equipped with high pressure, low pressure vacuum system, this is the first vacuum technology for width adjustment, which ensure the product flat, no shift during conveyor process, feeding position more accurate.

9. Adopts double motors, feeding & conveyor are adjusted independently, which is convenient for machine adjustment and good for different size product’s feeding, continuously working at the highest efficiency.

10. Equipped with OCR inspection system which imported from Italy or Swiss, to make sure system’s stability, no mis-judgement, no false rejection. The software was developed by us, tested by a large number of actual users, high in stability.

11. Mature system control and a number of invention patents reflect that no matter the paging precision and accuracy, rejection, and double detection are unique in the industry. The machine is working stable, which is convenient to integrate with other machine smoothly.

12. Multi-optional function module: double detection system, auto rectify system, auto rejection system, static elimination system, OCR inspection system, which can meet users’ kinds requirement.

13. Fully open feeding design, which realizes one machine with multi-channels and one machine with several sets of printers, then the efficiency multiply improved and greatly save labor cost. Users can change the feeding module according to the product’s feature. Feeding more smoother and adjustment easier.

14. Adopt streamline design, which is convenient to install kinds of printer or OCR inspection system, or labeling system etc. it realizes modular, high integration, which solved the disadvantage that kinds of technology to be realized on different machines, save labor cost and factory space.

15. Advanced intelligent feeding & printing platform “nine segment” classic design: feeding, double detection, rectify, corona, printing, OCR, rejection, curing (with high temperature resistant conveyor), collection. each station independent to each other and unified control, super cost effective machine, best choice for UV printing.

Reference Drawing

1. veterinary drugs, pesticides, seed, Chinese medicine, normal food packaging industry, “intelligent feeding & TTO thermal printing machine”, Model: BY-TF01-TTO

2. veterinary drugs, pesticides, seed, Chinese medicine, normal food packaging industry, intelligent feeding & UV printing machine Model: BY-TF01/02-400uv

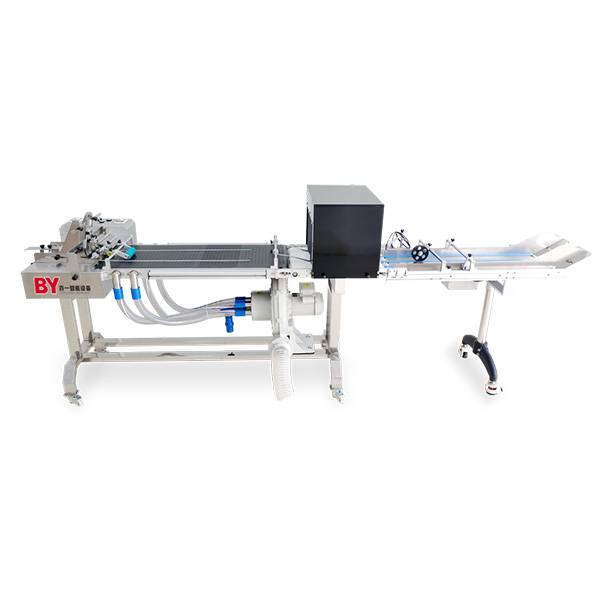

3. hotpot material packaging, “normal feeding & UV printing machine” Model: BY-SF04-400UV

4. medical device packaging industry use “Advance UDI code (normal code) inspection & rejection platform”, model: BY-HTF01-400/BY-HTF02-400

5. medical device packaging industry use “Advance UDI code (UV code) inspection & rejection platform”. Model: BY-HTF01-400UV/BY-HTF02-400UV

Technical parameter

1. Veterinary medicine, pesticide, seed, traditional Chinese medicine, general food packaging industry use Standard feeding & TTO thermal printing machine, Model: BY-TF01-TTO

A. dimension: L * W * H = 1350 * 800 * 1230mm

B. weight: about 100KG

C. Voltage: 220VAC, 50/60HZ

D. Power: about 1KW

E. belt running speed: 0-50m/min

F. controlling: PLC+HMI; Double frequency conversion / double DC brushless speed regulation

G. air: no need

H. feeding principle: classic friction, down -out feeding

I. conveyor method: with roller

J. available product: kinds of packaging bags, labels, paper etc soft prodct.

K. available product size: L*W*H=(60-300)*(60-400)*(0.1-1)mm

L. effective printing width: 300mm(handle adjustment)

M. machine body: stainless steel or carbon steel (color can be customized)

N. installation: floor stand, offline

O. optional function: auto collection, OCR inspection system, auto rejection

2. disposable face mask’s feeding & deliveryVeterinary medicine, pesticide, seed, traditional Chinese medicine, general food packaging industry use “intelligent feeding & UV printing machine” Model: BY-TF01/02-400uv

A.voltage: 220VAC, 50/60HZ

B. power: 2.5KW(including fan);

C. weight: 350kg

D. dimension: take the attached drawing for reference.

E. available product: normal carton box, cards, labels, plastic bags, manual.

F. available product size: L(60-300)* W(50-400)*H(0.05-3mm)

G. conveyor speed: 0-70m/min

H. controlling method: Double frequency conversion / double DC brushless speed regulation

I. feeding method: friction & down out feeding

J. double detection accuracy: 0.1mm

K. product input at one time: 100-300MM according to the product feature.

L. rejection method: there are three, flip & reject, push down or air blow.

M. rectify accuracy: 0.1-0.5mm according to the product (optional)

N. OCR inspection system: adopt Dalsa camera, and the software was developed by us.

O. optional function: double detection, auto rectify, OCR inspection system, auto rejection.

3. hot-pot material packaging industry “normal feeding & UV printing machine” Model: BY-SF04-400UV

A. dimension: L * W * H = 1700 * 640 * 800mm

B. Weight: 65KG

C. Voltage: 220VAC, 50/60HZ

D. Power: about 500W

E. efficiency: 0-300pcs/min(take the product size 100mm for reference)

F. belt running speed: 0-60m/min(continuous adjustment)

G. available product size: L * W * H = 60 – 300 * 60 – 280 * 0.1 – 3mm

H. Speed control method: Frequency conversion or DC brushless speed regulation

I. motor: Frequency conversion or DC brushless motor.

J. available product: kinds of paper, plastic bags, cards, labels etc.

K. machine body: stainless steel

L. installation: independent installation, floor stand

M. optional function: vacuum suction, auto collection.

4. medical device packaging industry use “advance UDI code (normal code) inspection & rejection platform” Model: BY-HTF01-400/BY-HTF02-400

A. Voltage: 220VAC, 50/60HZ

B. Power: 2.0KW(including fan);

C. weight: 350kg

D. dimension: take the drawing for reference

E. available product: normal carton box, cards, labels, plastic bags, manual

F. available product size: L(60-300) * W(50-400) * H(0.05-3mm)

G. conveyor speed: 0-100m/min

H. control method: Double frequency conversion speed regulation / double DC brushless speed regulation

I. feeding method: friction & down out feeding

J. double detection accuracy: 0.1mm

K. product input height at one time: 100-300mm according to the product feature

L. rejection method: “flip & reject” or “push down”, “air blow”

M. rectify accuracy: 0.1-0.5mm related with the product(optional function)

O. OCR inspection: adopt DASAL camera with our software.

P. optional function: double detection, auto rectify, OCR inspection system, auto rejection.

5. medical device packaging industry use “advance UDI code (UV code) inspection & rejection platform” Model: BY-HTF01-400UV/BY-HTF02-400UV

A. Voltage: 220VAC, 50/60HZ

B. power: 2.5KW(fan included);

C. weight: 450kg

D. dimension: take the drawing for reference.

E. available product: normal carton box, cards, labels, plastic bags, manual.

F. available product size: L(60-300) * W(50-400) * H(0.05-3mm)

G. conveyor speed: 0-100m/min

H. control method: Double frequency conversion speed regulation / double DC brushless speed regulation

I. feeding method: friction & down out feeding.

J. double detection accuracy: 0.1mm

K. product input height at one time: 100-300mm according to the product feature

L. rejection method: “flip & reject” or “push down”, “air blow”

M. rectify accuracy: 0.1-0.5mm related with the product(optional function)

O. OCR inspection: adopt DASAL camera with our software.

P. optional function: double detection, auto rectify, OCR inspection system, auto rejection.

Product detail pictures:

Related Product Guide:

Gaining client pleasure is our company's aim without end. We are going to make excellent efforts to create new and top-quality goods, meet your special requirements and provide you with pre-sale, on-sale and after-sale companies for Factory directly Diy Uv Printer Factories - Feeding & printing platform in special industry & special availability – Baiyi , The product will supply to all over the world, such as: Israel, Ottawa, Cambodia, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We are looking forward to cooperating with friends from all over the world.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!