Intelligent feeding & UV inkjet printing system

Feature: intelligent feeding & UV inkjet printing system, developed according to the requirement in some industry. It integrated with feeding system, plasma, UV inkjet printer, UV caring to make one complete application line. It adopts streamline working method with intelligent feeding module and conveyor platform. Speed fast, performance stable and many optional function, such as double detection, auto rectify, OCR inspection system, rejection system.

For feeding plat form, we have three types. The first one is with standard feeding parts, the second is with intelligent feeding part, the third one is with high speed feeding part.

The difference between standard feeding & UV inkjet printing system and Intelligent feeding & UV inkjet printing system is application. Standard feeding system adopts standard friction feeding principle, and it is suit for carton box, label, plastic bags feeding. While intelligent feeding system adopt static friction principle, the friction power can be adjusted more accurate, which make it suit for light, thin, soft and product with static electricity. Except that, there are some difference on structure and technology, both systems are coordinated with plasma, vacuum suction system, UV caring and auto collection conveyor as well as the UV light cover.

The difference between high speed feeding & UV inkjet printing system and intelligent feeding & UV inkjet printing system is the feeding platform. High speed feeding platform upgraded its configuration, speed faster, performance stable as well.

Here is the standard feeding & UV inkjet printing system picture below:

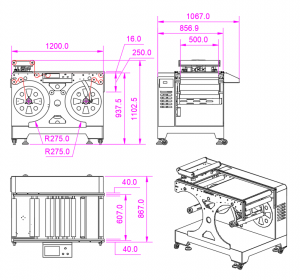

Here is the intelligent feeding & UV inkjet printing system picture below:

Here is the high speed intelligent feeding & UV inkjet printing system picture below: