Intelligent rewinding with UV inkjet printing system

Introduction

Feature:

Intelligent rewinding and encoding system is for various labels in roll, film in roll, paper in roll, weaving mark etc. products’ encoding requirement. According to rewinding’s production feature, we integrated it with our UV inkjet printer. People can choose to run the product step by step or continuously. Meanwhile, people can choose to use TIJ or CIJ inkjet printer, laser to replace the UV inkjet printer as well.

Intelligent rewinding with UV inkjet printing system is based on UV inkjet printing system’s technology, equipped with plasma and UV caring etc. it adopts 7” colorful HMI. PLC and micro PC for controlling. According to various film in roll, label in rolls’ structure and feature, we do the parameter setting in HMI and monitor the working status and alarm also. It controls the product release & collection tension, up & down on speed, anti-loosing, white mark or mark pulse, counting etc. it definitely realized intelligent control.

There is one optional function named Auto rectify system.

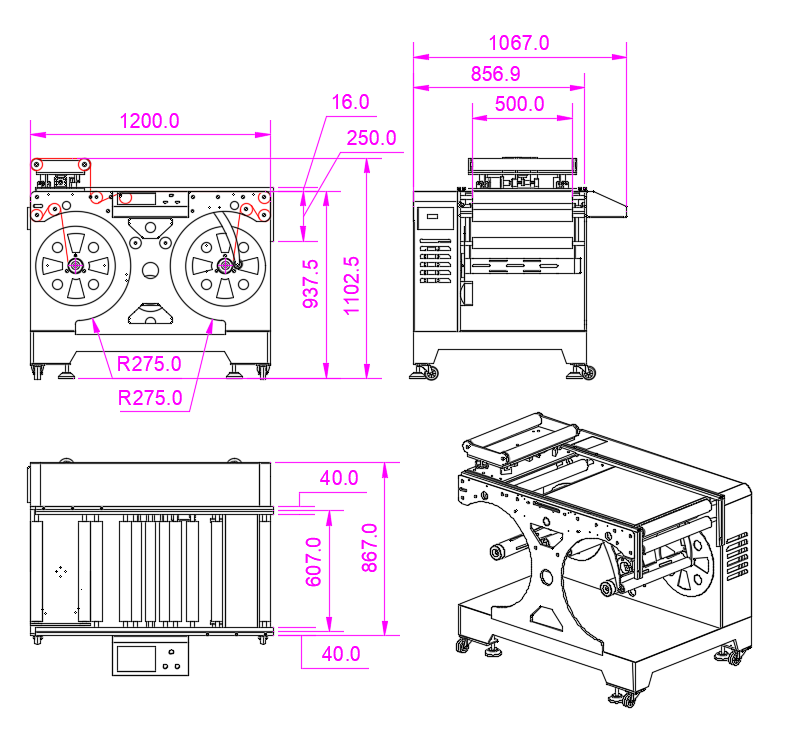

Reference drawing

Intelligent rewinding & UV inkjet printing system BY-SR500-UV

Equipment Technical Parameter

A,dimension:L*W*H=1200*1100*1200mm

B,weight:300KG

C,voltage:220VAC, 50/60HZ

D,power:about 2KW

E,efficiency:about 100-1000 pcs/min(take the product size 100mm for example,and the real production speed is related with UV inkjet printer.)

F,conveyor belt speed:10-100m/min(continuously adjustment)

G,available product size:30-480mm,max diameter 500mm;max weight for product in roll: 50KG

H,rectify method:framework rectify (optional function),accuracy: ±0.25mm

I,motor:servo motor.

J,available product:BOPP、CPP、PET、PE、paper、coated film、aluminizer etc. product in roll.

K,releasing tension control:linear tension control;

L,collection tension control:linear tension control;

M,inner core size:3”(76mm)

N,machine body:stainless steel or painted(color can be customized)

O,installation method:floor standard, off-line equipment.

Here is the system picture below: