Personlized Products Fully Automatic Rewinder for coding - KN95/KF94face mask feeding & printing system, disposable face mask feeder, high-speed intelligent disposable face mask feeder – Baiyi

Personlized Products Fully Automatic Rewinder for coding - KN95/KF94face mask feeding & printing system, disposable face mask feeder, high-speed intelligent disposable face mask feeder – Baiyi Detail:

Introduction

Series face mask feeder is developed for face mask production’s auto feeding & printing process and auto feeding & delivery technology process during the period of COVID19. It can be connected with earring welding machine, which realized auto stepping supply and auto continuous supply. It can modify the present “one for one, one for two” to independent working system and perfectly match the production efficiency of face mask production and earring welding and greatly raised the production and the machine’s stability.

According to the face mask material feature, it still adopts friction principle, integrates face mask feeding technology, we developed one special feeding structure to realize feeding & delivery. According to different technology feature, it can be separated to the equipment below:

1. “KN95/KF94 face mask feeding & printing system(model: BY-FT04-KN95/KF94)”;

2. “disposable face mask feeding system(model: BY-TF04-C)”;

3. “high speed intelligent disposable face mask feeding system(model: BY-HTF200-C)”.

1. “KN95/KF94 face mask feeding & printing machine” is aim to finish KN95 or KN94 face mask’s printing and it is based on the desk-top feeder and integrated with face mask’s feeding requirement, adopts food grade friction belt, powder free, which makes sure that face mask without deface; meanwhile it is also suit for semi-finished face mask with earring or without earring, single piece unsealed mask feeding. These three products can switch to use during the production freely. According to the production requirement, it also can equipped with TIJ printer or UV printer, which is to finish the encoding technology on face mask. People can print single color or colorful image or text information. It is to finish the face mask’s feeding & delivery as well as collection.

2. “disposable face mask’s feeding & delivery” and “high speed disposable face mask’s feeding & delivery” is developed for disposable face mask’s feeding & auto delivery, both adopts single friction belt as power source, equipped with fine texture friction pressing belt, which make it more suit for soft material. The difference of this two feeder is that the disposable face mask feeding & delivery is still based on the desk-top feeder, general purpose, working stable; the last one is developed for disposable face mask’s feeding & delivery. it belongs to specialized equipment. exquisite appearance, fast speed, high accuracy, high integration, it can perfectly integrated well with earring machine.

Reference Drawing

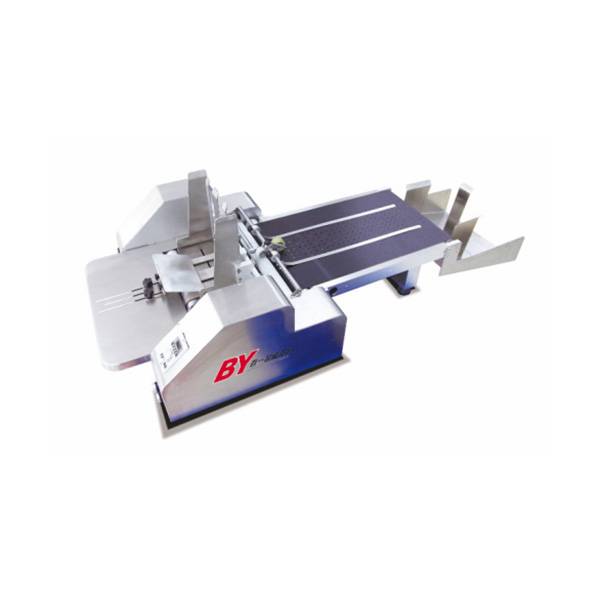

1. KN95/KF94 face mask feeding & printing machine

Desk-top type

Floor-standing type

2. disposable face mask’s feeding & delivery

3. high speed intelligent disposable face mask’s feeding & delivery

Equipment Technical Parameter

1. KN95/KF94 face mask feeding & printing

A. dimension: L * W * H = 1300 * 640 * 250mm

B. weight: 35KG

C. voltage: 220VAC, 50/60HZ

D. power: about 500W

E. efficiency: 0-300pcs/min

F. belt running speed: 0-60m/min(continuous adjustment)

G. available product range: take KN95/KF94 face mask and disposable face mask for reference.

H. speed control method: Frequency conversion or DC brushless speed regulation.

I. motor: Frequency conversion or DC brushless motor.

J. available product: disposable face mask, semi-finished face mask with or without earring, unsealed KN95/KN94 face mask.

K. machine body material: stainless steel.

L. installation: independent installation, desk-top or floor-standing.

M. optional function: vacuum fan suction, auto collection.

2. disposable face mask’s feeding & delivery

A. dimension: L * W * H = 1000 * 640 * 250mm

B. weight: 30KG

C. voltage: 220VAC, 50/60HZ

D. power: about 500W

E. efficiency: 0-300pcs/min

F. belt running speed: 0-60m/min(continuous adjustment)

G. available product: disposable face mask

H. speed control method: Frequency conversion or DC brushless speed regulation

I. motor: Frequency conversion or DC brushless motor.

J. machine body: stainless steel

K. installation method: independent installation, desk-top, it can be build-in control or external control.

L. optional function: vacuum fan suction .

3. high speed intelligent disposable face mask feeding & delivery

A. dimension: L * W * H = 470 * 240 * 690mm

B. weight: 15KG

C. voltage: 220VAC

D. power: about 600W

E. efficiency: 0-200pcs/min

F. belt running speed: 0-60m/min(continuous adjustment)

G. available product: disposable face mask

H. speed control method: servo + HMI + PLC

I. Motor: servo motor

J. machine body: stainless steel

k. installation method: independent installation, mini style, it can be build-in control or external control.

Product detail pictures:

Related Product Guide:

It adheres to the tenet "Honest, industrious, enterprising, innovative" to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for Personlized Products Fully Automatic Rewinder for coding - KN95/KF94face mask feeding & printing system, disposable face mask feeder, high-speed intelligent disposable face mask feeder – Baiyi , The product will supply to all over the world, such as: Tunisia, Paris, Argentina, We'll continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!