Professional China Friction Feeder - Feeding & TTO thermal printing all in one – Baiyi

Professional China Friction Feeder - Feeding & TTO thermal printing all in one – Baiyi Detail:

Introduction

Feeding & TTO thermal printing all in one series product is TTO thermal printing & intelligent feeding technology’s innovation integration. It realized auto feeding & TTO thermal printing’s coding perfectly and can be equipped with kinds of TT thermal printer. It is for kinds of plastic bags, paper, label etc. soft material’s coding. Adopts ribbon as printing substrate, sanitary & convenient, economical , physical characters beautiful. Classic “ three phases” design mode: 1,auto feeding;2,TTO thermal printing;3,collection in hopper;layout simple, operation & maintenance easy, scalability strong. according to application requirement in the market, there are four types: 1. Classic feeding & TTO thermal printing all in one , Model: BY-TF01-TTO; 2. Standard feeding & TTO thermal printing all in one, Type A, Model: BY-TF01/02-TTO-A; 3. Standard feeding & TTO thermal printing all in one, Type B, Model: BY-TF01/02-TTO-B;4,normal feeding & TTO thermal printing all in one, model :BY-SF01-TTO.

1. “classic feeding & TTO thermal printing all in one model: BY-TF01-TTO” s machine body adopts stainless steel or carbon steel painting ( color can be customized) . single friction belt as feeding power, equipped with different grades of friction pressing belt as well as different friction surface belt, which make it maximum suit for various material & size plastic bags, the product size can be from 80mm to 400mm. Classic roll transport method and installation method of embedded TTO thermal printer,equipped with double outside conveyor pressing belts, which make the product clamping from the feeding part to the printing area running stable. And no slip, no offset, and the efficiency perfect.

2. “Standard feeding & TTO thermal printing all in one, Type A” is based on the classic feeding & TTO thermal printing all in one, adopts intelligent feeder as feeding device, which make sure that the feeding parts accurate. The transmission parts adopts unique “roll & belt” method, which makes the machine function expandability except the TTO thermal printing. For example: labeling, inkjet printing, laser encoding, OCR detection, auto rejection, auto collection etc. Integrated with vacuum suction function during the transmission, it can satisfy the requirement of integrating kinds of technology all in one machine.

3. “standard feeding & TTO thermal printing all in one, Type B” also adopts intelligent feeder as feeding device. The difference to Standard feeding & TTO thermal printing all in one, Type A is adopting no roller transmission method and realized TTO thermal printing, which is the biggest innovation and experiment. Special making conveyor belt replaced the bearing roller under TTO thermal printing. So it not only support other extended function, but also greatly raised the printing accuracy. The position deviation is within ±0.2mm . meanwhile, printing speed, printing efficiency and stability all have a great improvement.

4. normal feeding & TTO thermal printing all in one is our most simple & TTO thermal printing machine. It adopts normal friction feeding system and integrated with roller & belt transmission method, suit for most plastic bags. Operation easy & economical. Its control adopts single motor and single frequency conversion speed regulation, No PLC or HMI, omit complicated human operation, extremely simple, easy on installation; lightweight body , convenient for shipment.

Reference Drawing

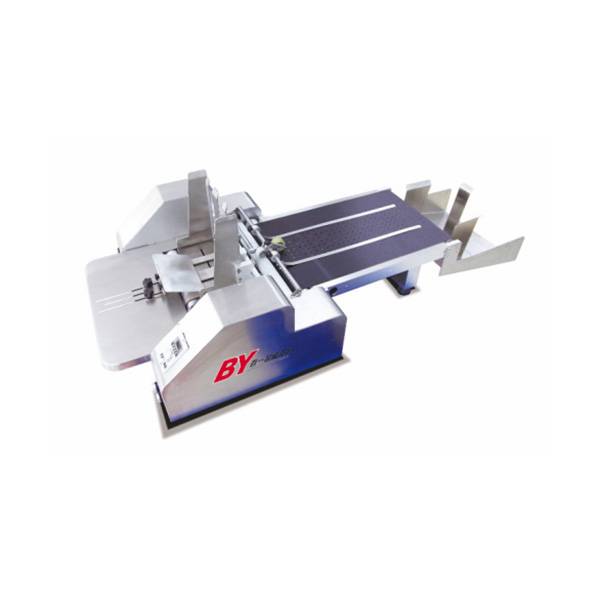

1. Classic feeding & TTO thermal printing all in one

2. Standard feeding & TTO thermal printing all in one Type A

3. Standard feeding & TTO thermal printing all in one Type B

4. normal feeding & TTO thermal printing all in one

Technical Parameter

1. Classic feeding & TTO thermal printing all in one

A. dimension: L * W * H = 1350 * 800 * 1230mm

B. Weight: about 100KG

C. Voltage: 220VAC 50/60HZ

D. Power: about 1KW

E. belt running speed: 0-50m/min

F. control: PLC+HMI; Double frequency conversion or double DC brushless speed regulation

G. air: no need

H. feeding principle: classic friction, button feeding

I. transmission method: roller method

J. available product: kinds of bags, labels, paper etc. soft material

K. available product size: L * W * H =(60-300) * (60-400) * (0.1-1)mm

L. effective printing width adjustment range: 300mm(handle adjustment)

M. machine body: stainless steel or carbon steel painting (color can be customized)

N. installation method: floor-stand off-line

O. optional function: auto collection, OCR, auto rejection.

2. disposable face mask’s feeding & deliverystandard feeding & TTO thermal printing all in one Type A

A. dimension: L * W * H = 2270 * 760 * 820mm (remark: conveyor belt width385mm, length: 1200mm)

B. weight: about 200KG

C. Voltage: 220VAC 50/60HZ

D. Power: about 1.5KW (including vacuum suction function)

E. belt running speed: 0-50m/min

F. control: PLC+HMI; Double frequency conversion or double DC brushless speed regulation

G. Air: no need

H. feeding principle: classic friction, button feeding

I. transmission method: roller together with belt

J. available product: kinds of packing bags, labels, paper etc. soft product.

K. available product size: L * W * H =(60-300) * (60-380) * (0.1-1)mm

L. effective printing width range: 300mm (handle adjustment)

M. machine body: stainless steel or carbon steel painting (color can be customized)

N. installation method: floor-stand and offline

O. optional function: labeling, OCR, auto rejection, auto collection.

3. Standard feeding & TTO thermal printing all in one Type B

A. dimension: L * W * H = 2270 * 760 * 820mm (Remark: standard conveyor belt width 385mm, length 800mm)

B. weight: about 200KG

C. Voltage: 220VAC 50/60HZ

D. Power: about 1KW

E. belt running speed: 0-50m/min

F. control: PLC+HMI; Double frequency conversion or double DC brushless speed regulation

G. Air: no need

H. feeding principle: classic friction, button feeding

I. transmission: no roller

J. available product: kinds of packing bags, labels, paper etc. soft product.

K. available product size: L * W * H =(60-300) * (60-380) * (0.1-1)mm

L. Effective printing width: 300mm(handle adjustment)

M. machine body: stainless steel or carbon steel painting(color can be customized)

N. installation method: floor -stand and offline

O. optional function: labeling, OCR, auto rejection, auto collection.

3. 4,Normal feeding & TTO thermal printing all in one

A. dimension: L * W * H = 1525 * 600 * 760mm (remark: standard conveyor belt width 330mm, length 600mm)

B. weight: about 100KG

C. voltage: 220VAC 50/60HZ.

D. Power: about 1KW

E. belt running speed: 0-50m/min

F. control method: single motor and single frequency conversion speed regulation

G. Air: no need

H. feeding principle: classic friction, button feeding

I. transmission method: roller together with belt

J. available product: kinds of packing bags, labels, paper etc. soft product.

K. available product size: L * W * H == (60-300) * (60-330) * (0.1-1)mm

L. effective printing width range: 200mm(handle adjustment)

M. machine body: stainless steel

N. installation method: floor stand and offline.

O. optional function: no.

Product detail pictures:

Related Product Guide:

We've numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for Professional China Friction Feeder - Feeding & TTO thermal printing all in one – Baiyi , The product will supply to all over the world, such as: Montreal, Denmark, Morocco, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!