professional factory for CIJ Inkjet Printer - intelligent vacuum picking-up, material input & feeding platform – Baiyi

professional factory for CIJ Inkjet Printer - intelligent vacuum picking-up, material input & feeding platform – Baiyi Detail:

Feature

Series product of “intelligent vacuum picking-up, material input & feeding platform” adopts vacuum suction cup, vacuum suction roller, vacuum belt etc. to pickup with vacuum to finish material input, which is totally different with friction feeding principle. The separating power is not only friction but with vacuum suction cup driving. So the structure is complex compared with friction. According to the usage requirement, it can realize these three feeding ways: up feeding, down feeding and side feeding. Up-feeding requires to stop the machine when material making-up. While down-feeding and side-feeding ‘s material making-up, no need to stop the machine. However, because of its feature of high stability, well protect the material, strong work beating, it is especially suit for kinds of wide format paper, label, plastic bags, woven bags’ auto input. It is widely used in printing, food packaging area.

Intelligent vacuum picking-up, material input & feeding platform is one independent working system, it can communicate with main machine and do the information exchange and assist main machine’s material input rhythmicity. Up-feeding type machine is most common.

According to different suction feature, it is separated into three types of feeder:

1. picking-up & material input with “suction cup” feeder(model: BY-VF550-S);

2, “picking-up & material input with suction roller feeder(model: BY-VF600-R);

3. picking-up & material input with suction belt feeder(model: BY-VF600-L), the difference of these three feeders is the available product and application scenarios.

For example: feeder with suction cup’s working speed is slow, which is suit for kinds of wide format & thin paper and labels, plastic bags. Suction roller feeder is fast speed, which is suit for long & wide paper & labels, plastic gabs; suction belt feeder is fast in speed, which is suit for kinds of thick & heavy carton box, card etc.

These three feeders adopt stainless steel as main material, it is with heavy machine body, which can reduce shock during the working period. Furthermore, because of its suction pick-p method, the most advantage comparing with the friction feeding is it can well protect the product surface, big size product is available and it can put a lot of product at one time. It makes up the friction feeding’s shortage. The size can be customized making.

For more information, pls click …www.bysd.net

Reference Drawing

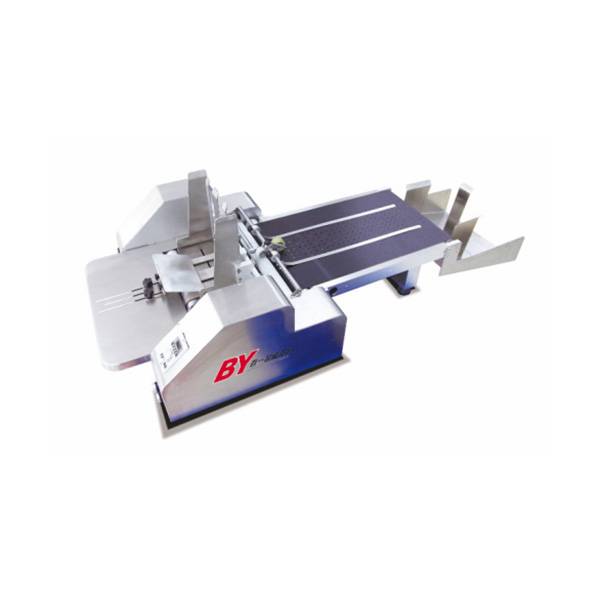

Picking-up & material input with suction cup feeder

Picking-up & material input with suction roller feeder

Picking-up & material input with suction belt feeder

Technical parameter

Picking-up & material input with suction cup feeder

1.dimension: L * W * H = 1700 * 1450 * 1090mm

2. weight: 300KG

3. voltage: 220VAC, 50/60HZ

4. Power: about 1.5KW

5. efficiency: 0-120pcs/min;

6. belt running speed: 0-60m/min(continuously adjustment)

7. available product size: L * W * H = 100-500 * 100-500 * 0.1-0.5mm

8. material stack height at one time: 500mm

9. speed control method: Variable frequency or brushless DC motor

10. motor: Variable frequency or brushless DC motor

11. available product: kinds of wide format paper, plastic bags, labels etc.

12. machine body: stainless steel or painted carbon steel.

13. installation: independent installation, floor stand.

14. optional function: can be customized.

Picking-up & material input with suction roller feeder

1.dimension: L * W * H = 2230 * 1355 * 1070mm

2. weight: 400KG

3. voltage: 220VAC, 50/60HZ

4. power: about 1.5KW

5. efficiency: 0-500pcs/min

6. belt running speed: 0-60m/min(continuously adjustment)

7. available product: L*W*H=100-600*100-600*0.1-0.5mm

8. material stack at one time: 500mm

9. speed control method: Variable frequency or brushless DC motor

10. motor: Variable frequency or brushless DC motor

11. available product: kinds of wide format paper, labels etc.

12. machine body: stainless steel or painted carbon steel

13. installation method: independent installation, floor stand

14. optional function: can be customized.

Picking-up & material input with suction belt feeder

1. dimension: L * W * H = 2200 * 1355 * 1070mm

2. weight: 400KG

3. voltage: 220VAC, 50/60HZ

4. power: about 1.5KW

5. efficiency: 0-500pcs/min

6. belt running speed: 0-60m/min(continuously adjustment)

7. available product: L * W * H = 100-600 * 100-600 * 0.1-0.5mm

8. material stack at one time: 500mm

9. speed control method: Variable frequency or brushless DC motor

10. motor: Variable frequency or brushless DC motor

11. available product: kinds of wide format thick carton box etc.

12. machine body: stainless steel or painted carbon steel.

13. installation method: independent installation, floor stand.

14. optional function: can be customized.

Product detail pictures:

Related Product Guide:

We're proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for professional factory for CIJ Inkjet Printer - intelligent vacuum picking-up, material input & feeding platform – Baiyi , The product will supply to all over the world, such as: Estonia, Berlin, Canada, Adhering to the management tenet of "Managing Sincerely, Winning by Quality", we try our best to provide excellent products and service to our clients. We look forward to making progress together with domestic and international clients.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!