Renewable Design for Rewinder for label - series of Intelligent feeding platform – Baiyi

Renewable Design for Rewinder for label - series of Intelligent feeding platform – Baiyi Detail:

Introduction

Intelligent feeding platform is developed according to the high requirement in the industry. All adopts streamline working mode and intelligent feeding modular. Fast in speed, good in stability, strong in function, good in feature, rich in optional function. It is not only suit for kinds of product, but also has very well experience for user operation. This platform adopts high-strength structure and first-class brand electrical components to make sure the usage stability.

It has dozens of items patent technology and adopts precision process technology and strict quality control methods, which make this series product having a strong quality advantage. According to different application, there are five products:

1. standard intelligent printing platform(Model: BY-TF01/02-400);

2. standard intelligent feeding & V printing platform(Model: BY-TF01/02-400(UV));

3. High-speed intelligent feeding & printing platform(Model: BY-HTF01/02-400);

4. High-speed intelligent feeding & UV printing platform(Model: BY-HTF01/02-400(UV));

5. Multi-channels intelligent feeding & printing platform(Model: BY-MTF02-400).

The Max difference between “standard intelligent feeding & printing platform” and “standard intelligent feeding &UV printing platform” is application occasion. Standard intelligent feeding & printing platform is suit for normal product’s coding application. Such as TIJ, CIJ, Laser etc. Standard intelligent feeding & UV printing platform is equipped with Palsma for product surface process and curing station, which is suit for UV printing system. There are some difference on technology.

“High-speed intelligent feeding & printing platform” and “High-speed intelligent feeding& UV printing platform” did the upgrade for configuration based on the standard platform. Speed is faster, stability is stronger. Machine body adopts stainless steel or carbon steel with painting (color can be customized), fully enclosed design, more texture. These 4 types equipment because of their solid body and accurate performance, they can be equipped with some optional function such as double detection system, auto-rectify system, visual inspection system, auto-rejection system. These optional functions make the equipment more intelligent and unmanned.

Multi-channel intelligent feeding & printing platform is based on standard platform and it is to max raise efficiency and reduce labor costs. There are two or more product running channels. People can adjust the feeding unit to one product running channel flexibly then suit for big product. It is one of our max high-efficiency product.

Drawing for Reference

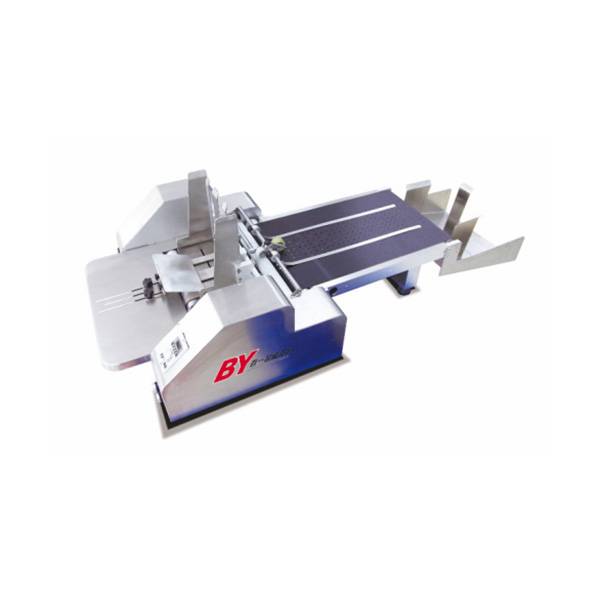

1. Standard intelligent feeding & printing platform

2. standard intelligent feeding & UV printing platform

3. High-speed intelligent feeding & printing platform

3. High-speed intelligent feeding & UV printing platform

Equipment Parameter

1. standard intelligent feeding & printing platform

A. dimension: L * W * H=3000 * 763 * 820mm

B. weight: about 150-200KG

C. voltage: 220VAC 50/60HZ

D. Power: about 2KW

E. belt running speed: 0-60m/min

F. control: double frequency conversion/double DC brushless speed regulation

G. air: no need

H. feeding principle: intelligent friction, bottom delivery.

I. conveyor method: vacuum conveyor belt

J. available product: kinds of paper box, packing bags, label, paper, manual etc.

K. available product size: L * W * H =(60-300) * (30-400) * (0.05-3)mm

L. product running accuracy: ±1.5mm

M. machine body material: stainless steel or carbon steel with painting(color can be customized)

N. installation method: floor-standing, off-line, external support.

O. standard configuration: intelligent feeding & vacuum suction conveyor & auto collection.

P. optional function: double detection, auto-rectify, visual inspection system, auto-rejection.

2. standard intelligent feeding & UV printing platform

A. dimension: L * W * H = 3600 * 763 * 820mm

B. weight: about 200KG

C. voltage: 220VAC 50/60HZ

D. power: about 2KW

E. belt running speed: 0-60m/min

F. control: double frequency conversion/double DC brushless speed regulation

G. air: no need

H. feeding principle: intelligent friction, bottom delivery.

I. conveyor method: vacuum conveyor belt

J. available product: kinds of paper box, packing bags, label, paper, manual etc.

K. available product size: L * W * H =(60-300) * (30-400) * (0.05-3)mm

L. product running accuracy: ±1.5mm

M. machine body material: stainless steel or carbon steel with painting(color can be customized)

N. installation method: floor-standing, off-line, external support.

O. standard configuration: intelligent feeding & vacuum suction conveyor & high temperature resistant transportation & auto-collection

P. optional function: double detection, auto-rectify, visual inspection system, auto-rejection.

3. High-speed intelligent feeding & printing platform

A. dimension: L * W * H = 3000 * 763 * 820mm

B. weight: about 200-250KG

C. voltage: 220VAC 50/60HZ

D. Power: about 2KW

E. belt running speed: 0-100m/min

F. control: double frequency conversion/double DC brushless speed regulation

G. air: no need

H. feeding principle: intelligent friction, bottom delivery.

I. conveyor method: vacuum conveyor belt

J. available product: kinds of paper box, packing bags, label, paper, manual etc.

K. available product size: L * W * H =(60-300) * (30-400) * (0.05-3)mm

L. product running accuracy: ±1.5mm

M. machine body material: stainless steel or carbon steel with painting(color can be customized)

N. installation method: floor-standing offline, cabinet type.

O. standard configuration: intelligent feeding & vacuum conveyor & auto-collection.

P. optional function: double detection, auto-rectify, visual inspection system, auto-rejection.

4. High-speed intelligent feeding & UV printing platform

A. dimension: L * W * H = 4220 * 763 * 820mm

B. weight: about 250-300KG

C. voltage: 220VAC 50/60HZ

D. power: about 2.5KW

E. belt running speed: 0-100m/min

F. control: double frequency conversion/double DC brushless speed regulation

G. air: no need

H. feeding principle: intelligent friction, bottom delivery.

I. conveyor method: vacuum conveyor belt

J. available product: kinds of paper box, packing bags, label, paper, manual etc.

K. available product size: L * W * H =(60-300) * (30-400) * (0.05-3)mm

L. product running accuracy: ±1.5mm

M. machine body material: stainless steel or carbon steel with painting(color can be customized)

N. installation method: floor-standing offline, cabinet type.

O. standard configuration: intelligent feeding & vacuum conveyor & high temperature resistance conveyor & auto collection

P. optional function: double detection, auto-rectify, visual inspection system, auto-rejection.

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for Renewable Design for Rewinder for label - series of Intelligent feeding platform – Baiyi , The product will supply to all over the world, such as: moldova, Colombia, Brunei, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.